Fucich LLC gets called for emergency tube repairs often. We also do planned tube replacement and repairs. We have skilled tube welders that are mirror tested in a simulated test jig.

We recently sent tube welders to a power plant in Trinidad. They cut four T-91 tubes on the 1st row, three T-91 tubes on the 2nd row and cut out a section of T-91 tube on the 3rd row and welded in a dutchman. The dutchman welds were x-rayed and heat treated then the tubes that were cut were welded back, x-rayed and heat treated per row.

We cut sections of HP Evap tube out for tube samples all the time. We will either x-ray the welds or perform a progressive MT on the welds as instructed by the Plant.

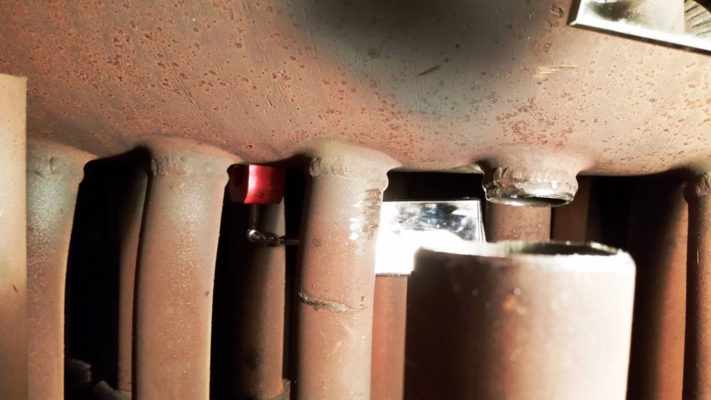

We commonly repair tube leaks by cutting a window in the tube header(s) and plugging the tube(s) that leak by welding a plug inside the header and then welding the window back into the header.

Fucich LLC has welding procedures in place for welding tube and tube to headers for just about all materials. If we don’t have a procedure for a certain material we will qualify one.